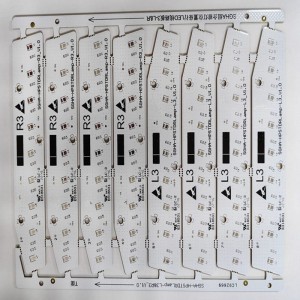

Ngwa ngwa ntụgharị pcb elu ọgwụgwọ HASL LF RoHS

Nkọwapụta ngwaahịa:

| Ihe ndabere: | FR4 TG140 |

| Ọkpụrụkpụ PCB: | 1.6+/-10% mm |

| Ọnụọgụ oyi akwa: | 2L |

| Ọkpụrụkpụ ọla kọpa: | 1/1 oz |

| Ọgwụgwọ elu: | HASL-LF |

| Ihe mkpuchi ihe na-ere ahịa: | Ọcha |

| Ihuenyo silk: | Nwa |

| Usoro pụrụ iche: | Ọkọlọtọ |

Ngwa

Usoro HASL nke sekit na-ezo aka na pad HASL usoro, nke bụ ịkwanye tin na pad na n'elu nke bọọdụ sekit. Ọ nwere ike ịrụ ọrụ nke mgbochi corrosion na mgbochi oxidation, ma nwee ike ịbawanye mpaghara kọntaktị n'etiti pad na ngwaọrụ a na-ere ere, ma melite ntụkwasị obi nke soldering. Usoro a kapịrị ọnụ gụnyere ọtụtụ usoro dị ka ihicha, ntinye kemịkalụ nke tin, ntu, na nchacha. Mgbe ahụ, na usoro dị ka ire ere ikuku na-ekpo ọkụ, ọ ga-emeghachi omume iji mepụta njikọ n'etiti tin na ngwaọrụ splice. Tin spraying na bọọdụ sekit bụ usoro a na-ejikarị eme ihe ma na-ejikarị eme ihe na ụlọ ọrụ na-emepụta ngwá electronic.

Lead HASL na HASL na-enweghị ụzọ bụ teknụzụ ọgwụgwọ elu abụọ a na-ejikarị echebe akụkụ ọla nke bọọdụ sekit site na corrosion na oxidation. N'ime ha, ihe mejupụtara lead HASL bụ 63% tin na 37% lead, ebe HASL enweghị ndu bụ tin, ọla kọpa na ụfọdụ ihe ndị ọzọ (dị ka ọlaọcha, nickel, antimony, wdg). Tụnyere HASL dabere na ndu, ọdịiche dị n'etiti HASL na-enweghị ndu bụ na ọ na-eme enyi na gburugburu ebe obibi, n'ihi na ndu bụ ihe na-emerụ ahụ nke na-etinye gburugburu na ahụike mmadụ. Na mgbakwunye, n'ihi ihe dị iche iche dị na HASL na-enweghị ndu, ire ere ya na akụrụngwa eletrik dịtụ iche, ọ dịkwa mkpa ka ahọpụtara ya dịka ngwa chọrọ. N'ikwu okwu n'ozuzu, ọnụ ahịa HASL na-enweghị ndu dị ntakịrị elu karịa nke ndu HASL, mana nchebe gburugburu ebe obibi na arụmọrụ ya ka mma, ọtụtụ ndị ọrụ na-akwado ya.

Iji rube isi na ntuziaka RoHS, ngwaahịa bọọdụ sekit kwesịrị imezu ọnọdụ ndị a:

1. Ọdịnaya nke ndu (Pb), mercury (Hg), cadmium (Cd), chromium hexavalent (Cr6 +), polybrominated biphenyls (PBB) na polybrominated diphenyl ethers (PBDE) kwesịrị ịdị ala karịa ọnụ ahịa njedebe akọwapụtara.

2. Ọdịnaya nke ọla dị oke ọnụ ahịa dị ka bismuth, ọlaọcha, ọla edo, palladium, na platinum kwesịrị ịdị na oke ezi uche.

3. Ọdịnaya halogen kwesịrị ịbụ ihe na-erughị uru njedebe akọwapụtara, gụnyere chlorine (Cl), bromine (Br) na ayodiin (I).

4. Igwe sekit na ihe ndị mejupụtara ya kwesịrị igosi ọdịnaya na ojiji nke ihe ndị dị mkpa na-egbu egbu na ndị na-emerụ ahụ. Ihe a dị n'elu bụ otu n'ime isi ọnọdụ maka bọọdụ sekit iji rube isi na ntuziaka RoHS, mana ọ dị mkpa ka ekpebie ihe ndị a kapịrị ọnụ dịka ụkpụrụ na ụkpụrụ mpaghara siri dị.

Ajụjụ

HASL ma ọ bụ HAL (maka ikuku na-ekpo ọkụ (solder) larịị) bụ ụdị mmecha ejiri na bọọdụ sekit ebipụtara (PCB). A na-etinyekarị PCB n'ime ebe ịsa ahụ a wụrụ awụ ka ọ bụrụ ihe na-ere ya kpuchie elu ọla kọpa niile. A na-ewepụ ihe na-ere ngafe site na ịgafe PCB n'etiti mma ikuku na-ekpo ọkụ.

HASL (Standard): Nke a na-ahụkarị Tin-Lead - HASL (Nduzi efu): Tin-Copper, Tin-Copper-Nickel, ma ọ bụ Tin-Copper-Nickel Germanium. Ụdị ọkpụrụkpụ: 1UM-5UM

Ọ naghị eji Tin-Lead solder. Kama, enwere ike iji Tin-Copper, Tin-Nickel ma ọ bụ Tin-Copper-Nickel Germanium mee ihe. Nke a na-eme HASL na-enweghị Lead ka ọ bụrụ nhọrọ dabara adaba na RoHS.

Igwe ọkụ na-ekpo ọkụ (HASL) na-eji lead dị ka akụkụ nke alloy ya, nke a na-ewere na ọ na-emerụ mmadụ. Agbanyeghị, ọkwa ọkwa ikuku na-ekpo ọkụ na-enweghị Lead (LF-HASL) anaghị eji lead dị ka alloy solder ya, na-eme ka ọ dị mma maka mmadụ na gburugburu ebe obibi.

HASL bụ nke akụ na ụba na ebe niile

Ọ nwere ezigbo solderability na ezigbo ndụ shelf.