Ngwa ụlọ nyocha anụ ahụ na kemịkalụ:

Nnwale igwe, nnwale eletriki, nyocha na ule bọọdụ mbụ, nyocha ụlọ nyocha.

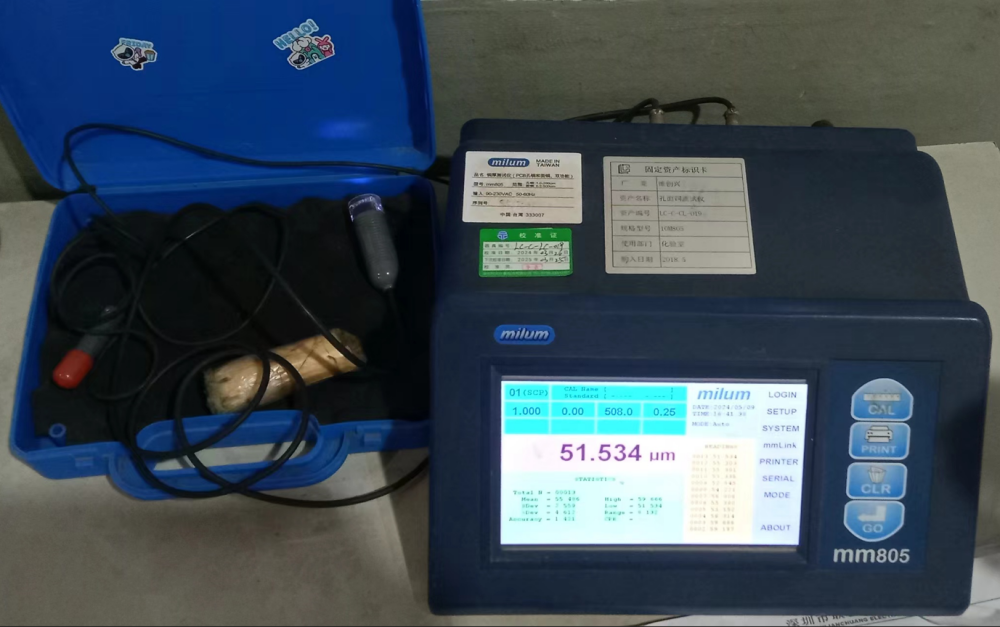

1. Ọla kọpa foil tester: A na-eji ngwá ọrụ a tụọ ike ike nke foil ọla kọpa n'oge usoro ịgbatị ahụ. Ọ na-enyere aka nyochaa ike na ike nke foil ọla kọpa iji hụ na ịdị mma ngwaahịa na ntụkwasị obi.

Ọla kọpa foil Tester

Igwe nleba anya nke nwere ọgụgụ isi nke nnu zuru oke

2. Igwe nyocha ịgba nnu nwere ọgụgụ isi zuru oke na-akpaghị aka: Igwe a na-eme ka gburugburu ebe ịgba nnu nnu iji nwalee nguzogide corrosion nke mbadamba sekit mgbe ọgwụgwọ elu gachara. Ọ na-enyere aka ịchịkwa ogo ngwaahịa ma hụ na arụmọrụ kwụsiri ike na gburugburu ebe siri ike.

3. Igwe nyocha nke waya anọ: Ngwá ọrụ a na-anwale nguzogide na conductivity nke wires na mbadamba sekit e biri ebi. Ọ na-enyocha arụmọrụ eletriki nke osisi ahụ, gụnyere ọrụ nnyefe na ike oriri, iji hụ na njikọ a pụrụ ịdabere na ya na nke kwụsiri ike.

Igwe nyocha waya anọ

4. impedance tester: bụ ngwá ọrụ dị mkpa n'imepụta bọọdụ sekit e biri ebi. A na-eji ya tụọ uru impedance dị na bọọdụ sekit site n'ịmepụta akara ngosi AC ugboro ugboro nke na-agafe sekit n'okpuru ule. Sekit nha wee gbakọọ uru impedance dabere na iwu Ohm na njirimara sekit AC. Nke a na-eme ka a mata na bọọdụ sekit a na-emepụta na-ezute ihe mgbochi mgbochi nke onye ahịa setịpụrụ.

Ndị na-emepụta ihe nwekwara ike iji usoro nyocha a iji mee ka nhazi usoro ma welie ikike njikwa impedance nke bọọdụ sekit. Nke a dị mkpa iji gboo mkpa nke mgbasa ozi dijitalụ dị elu yana ngwa ugboro redio.

Ihe nnwale impedance

N'ime usoro mmepụta sekit, a na-eme nnwale impedance na ọkwa dị iche iche:

1) Ogbo imewe: Ndị injinia na-eji sọftụwia simulation electromagnetic iji chepụta na nhazi bọọdụ sekit. Ha na-ebu ụzọ gbakọọ ma na-egosipụta ụkpụrụ impedance iji hụ na imewe ahụ na-emezu ihe achọrọ. Simulation a na-enyere aka nyochaa impedance nke bọọdụ sekit tupu imepụta ya.

2) Oge mmalite nke nrụpụta: N'oge mmepụta prototype, a na-eme nnwale impedance iji chọpụta na uru impedance kwekọrọ na atụmanya. Enwere ike ime mgbanwe na usoro mmepụta ihe dabere na nsonaazụ ndị a.

3) Usoro nrụpụta: N'imepụta bọọdụ sekit nke multi-layer, a na-eme nnwale impedance na ọnụ ọnụ dị oke mkpa iji hụ na njikwa parampat dị ka ọkpụrụkpụ foil ọla kọpa, ọkpụrụkpụ ihe dielectric, na obosara ahịrị. Nke a na-ekwe nkwa na uru impedance ikpeazụ na-emezu ihe achọrọ imewe.

4) Nlebanya ngwaahịa emechara: Mgbe emechara, a na-eme ule impedance ikpeazụ na bọọdụ sekit. Nke a na-eme ka njikwa na mgbanwe ndị a na-eme n'oge niile na-emepụta ihe na-eme ka ọ dị mma na-emezu ihe a chọrọ maka imewe maka uru impedance.

5. Igwe nyocha dị ala: Igwe a na-anwale nguzogide nke wires na kọntaktị kọntaktị na bọọdụ sekit iji hụ na ha na-emezu ihe ndị a chọrọ ma hụ na ngwaahịa ngwaahịa na arụmọrụ.

Igwe nleba anya dị ala

Ihe nnwale na-efe efe

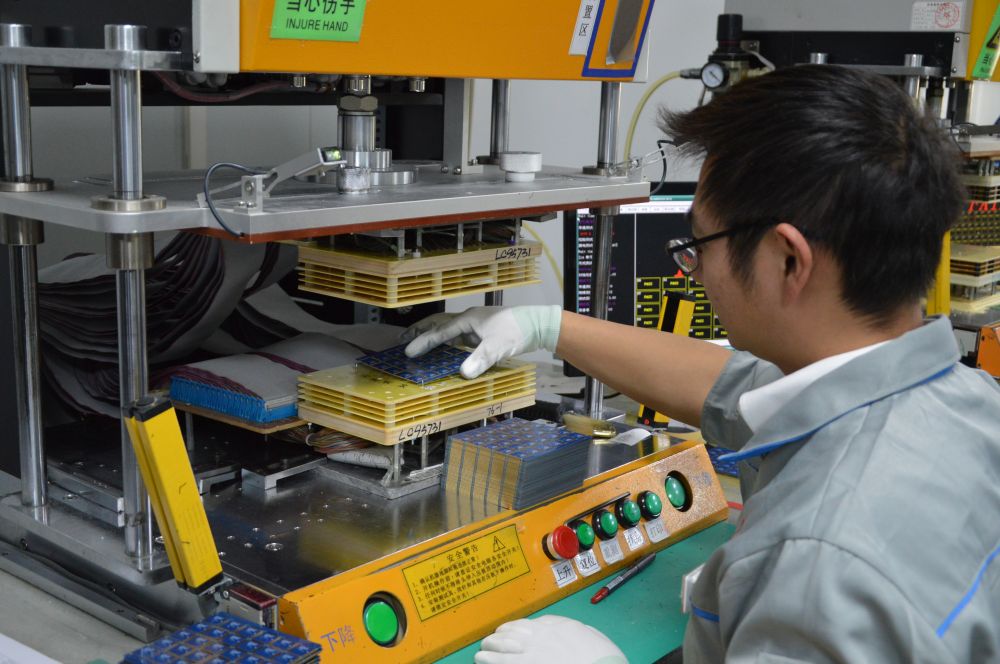

6. Nnwale nyocha nke na-efe efe: A na-eji ihe nleba anya nke na-efe efe na-anwale ụkpụrụ mkpuchi na ụkpụrụ omume nke bọọdụ sekit. Ọ nwere ike nyochaa usoro ule wee chọpụta ihe ndị na-adịghị mma na ozugbo, na-eme ka ule ziri ezi. Nnwale nyocha nke na-efe efe dabara adaba maka nnwale obere obere na ọkara, n'ihi na ọ na-ewepụ mkpa maka nyocha ule, na-ebelata oge mmepụta na ọnụ ahịa.

7. Fixture tooling tester: Dị ka ule nyocha na-efe efe, a na-ejikarị ule ule nyocha maka ule ọkara na nnukwu ogbe sekit. Ọ na-enyere nnwale n'otu oge nke ọtụtụ ihe ule, na-emeziwanye arụmọrụ ule na ibelata oge ule. Nke a na-eme ka arụpụta ọrụ zuru oke nke ahịrị mmepụta ahụ, ebe ọ na-eme ka ọ dị mma na nke ukwuu.

Ihe nleba anya ngwa ngwa ngwa

Ihe nlebanya nrụnye akpaaka

Ụlọ Ahịa Ngwa Ngwa

8. Ngwa ihe atụ akụkụ abụọ: Ngwa a na-ese foto nke elu ihe site na ọkụ na foto. Ọ na-ahazi ihe onyonyo a wee nyochaa data iji nweta ozi geometric gbasara ihe ahụ. A na-egosipụta nsonaazụ ya n'ọhụụ, na-enye ndị na-arụ ọrụ ohere ịhụ ma tụọ nha, nha, ọnọdụ, na njirimara ndị ọzọ nke ihe ahụ.

Ngwa eji atụ akụkụ abụọ

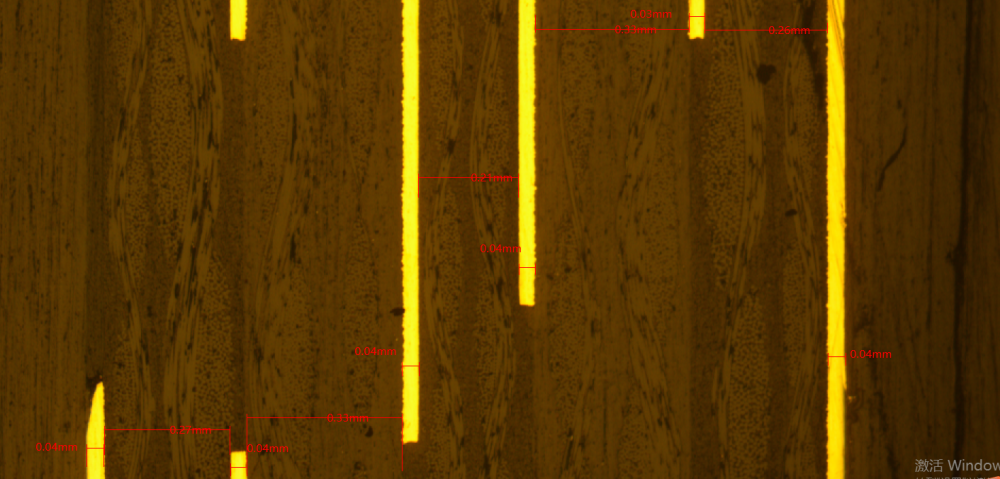

Ngwa eji atụ obosara ahịrị

9. Line obosara nha ngwá: The akara obosara nha ngwá bụ isi na-eji tụọ elu na ala obosara, ebe, n'akuku, okirikiri dayameta, gburugburu center anya, na ndị ọzọ parameters nke e biri ebi circuit osisi si ọkara emechara ngwaahịa mgbe mmepe na etching (tupu ibipụta solder nkpuchi ink). Ọ na-eji isi iyi ọkụ na-amụnye bọọdụ sekit ma weghara akara ngosi ihe onyonyo site na nkwalite ngwa anya na ngbanwe akara fotoelectric CCD. A na-egosipụtakwa nsonaazụ nha na kọmpụta, na-enye ohere maka nha nke ọma na nke ọma site na ịpị onyonyo a.

10. Tin oven: The tin oven na-arụrụ ọrụ iji nwalee solderability na thermal ujo iguzogide nke sekit mbadamba, n'ịhụ àgwà na ntụkwasị obi nke solder nkwonkwo.

Nnwale solderability: Nke a na-enyocha ikike elu elu sekit ahụ iji mepụta nkekọ solder a pụrụ ịdabere na ya. Ọ na-atụle ihe kọntaktị iji nyochaa njikọ dị n'etiti ihe na-ere ihe na elu osisi sekit.

Nnwale nguzogide okpomọkụ: Nnwale a na-enyocha nkwụsi ike nke bọọdụ sekit na mgbanwe ọnọdụ okpomọkụ na gburugburu oke okpomọkụ. Ọ na-agụnye ikpughe bọọdụ sekit na okpomọkụ dị elu ma na-ebufe ya ngwa ngwa na okpomọkụ dị ala iji nyochaa nguzogide okpomọkụ ya.

11. Igwe nyocha X-Ray: Igwe nyocha X-ray nwere ike ịbanye na bọọdụ sekit na-enweghị mkpa ịkwasa ma ọ bụ mebie, si otú ahụ na-ezere ụgwọ na mmebi nwere ike. Ọ nwere ike ịchọpụta ntụpọ dị na bọọdụ sekit, gụnyere oghere afụ, sekit mepere emepe, obere sekit, na ahịrị adịghị mma. Akụrụngwa na-arụ ọrụ n'onwe ya, na-ebunye ma na-ebutu ihe na-akpaghị aka, na-achọpụta, nyochaa, na-achọpụta ihe ndị na-adịghị mma, na-akanye akara na akara na-akpaghị aka, si otú ahụ na-emeziwanye mmepụta mmepụta ihe.

Igwe nyocha X-ray

Mkpuchi Ọkpụrụkpụ Nleba

12. Ihe mkpuchi mkpuchi mkpuchi: N'oge a na-emepụta bọọdụ sekit, a na-etinyekarị ihe mkpuchi dị iche iche (dịka tin plating, plating gold, wdg) iji kwalite conductivity na mgbochi corrosion. Otú ọ dị, ọkpụrụkpụ mkpuchi na-ekwesịghị ekwesị nwere ike ịkpata nsogbu arụmọrụ. A na-eji ihe mkpuchi mkpuchi na-eme ka ọkpụkpụ nke mkpuchi dị n'elu osisi sekit, hụ na ọ na-emezu ihe ndị a chọrọ.

13. Ngwa ROHS: N'imepụta bọọdụ sekit a na-ebipụta, a na-eji ngwá ọrụ ROHS arụ ọrụ iji chọpụta na nyochaa ihe ndị na-emerụ ahụ na ihe, na-eme ka nrube isi n'iwu nke ROHS. Ntuziaka ROHS, nke European Union mebere, na-amachibido ihe ndị dị ize ndụ na ngwa eletrọnịkị na eletriki, gụnyere lead, mercury, cadmium, hexavalent chromium, na ndị ọzọ. A na-eji ngwa ROHS tụọ ọdịnaya nke ihe ndị a na-emerụ ahụ, na-ahụ na ihe ndị a na-eji na-emepụta bọọdụ sekit a na-ebipụta na-emezu ihe iwu ROHS chọrọ, na-ahụ na nchekwa ngwaahịa na nchekwa gburugburu ebe obibi.

Ngwa ROHS

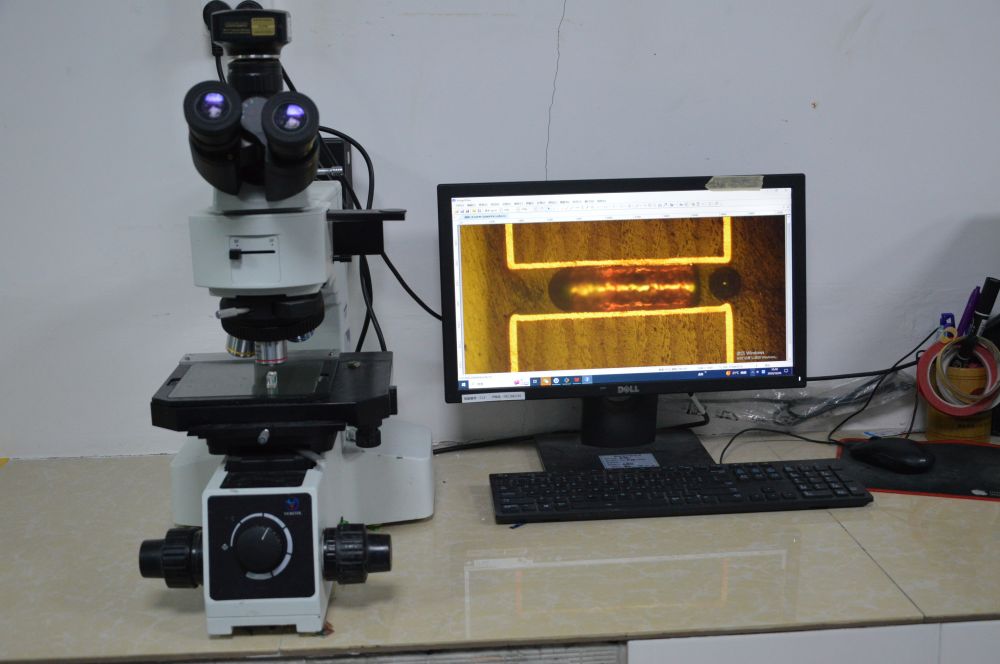

14. Metallographic mikroskopu: The metallographic microscope bụ isi na-eji na-enyocha ọla kọpa ọkpụrụkpụ nke n'ime na elu n'ígwé, electroplated elu, electroplated oghere, solder masks, elu agwọ ọrịa, na ọkpụrụkpụ nke ọ bụla dielectric oyi akwa izute ndị ahịa nkọwa.

Ụlọ ahịa Nkebi Microscopic

Nkeji anya nke 1

Nkeji microscopic nke 2

Oghere dị n'elu ọla Tester

15. Oghere n'elu ọla kọpa tester: Nke a ngwá na-eji nwalee ọkpụrụkpụ na uniformity nke ọla kọpa foil na oghere nke e biri ebi sekit mbadamba. Site n'ịchọpụta ngwa ngwa akwa ọla kọpa na-ekwekọghị ekwekọ ma ọ bụ ndịiche sitere na nso nso a kapịrị ọnụ, enwere ike ime mgbanwe na usoro mmepụta n'oge.

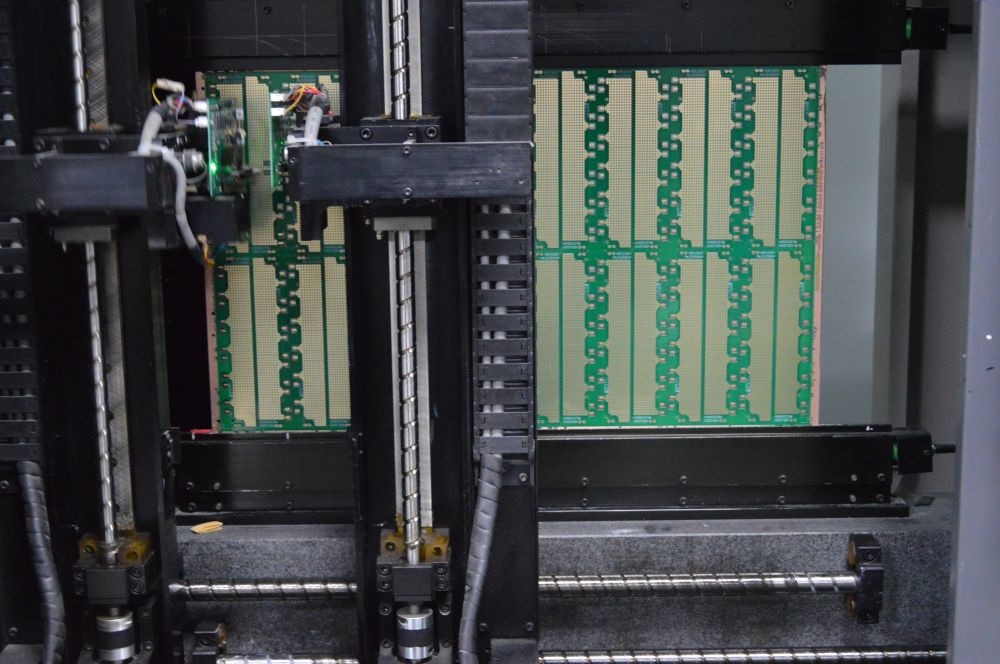

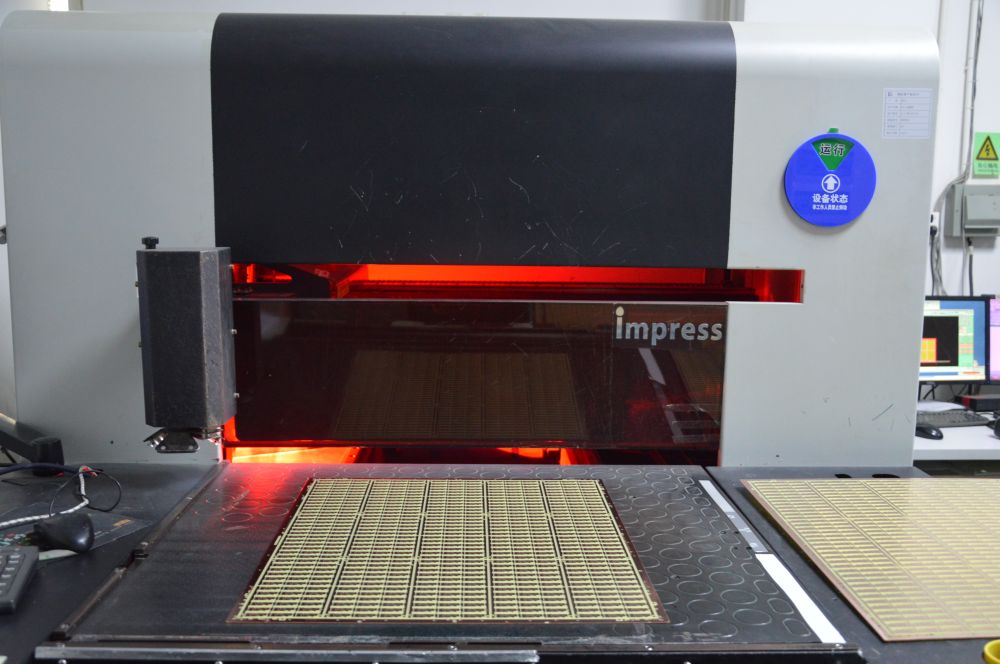

16. The AOI Scanner, mkpụmkpụ maka Automated Optical Inspection, bụ ụdị ngwá ọrụ na-eji ngwa anya technology na-akpaghị aka na-achọpụta electronic components ma ọ bụ ngwaahịa. Ọrụ ya gụnyere ịse foto dị elu nke ihe a na-enyocha site na iji usoro igwefoto dị elu. N'ikpeazụ, a na-eji teknụzụ nhazi ihe oyiyi kọmputa arụ ọrụ iji nyochaa na atụnyere ihe oyiyi ahụ, na-eme ka nchọpụta nke ntụpọ elu na mmebi nsogbu dị n'ihe a chọrọ.

Ihe nyocha AOI

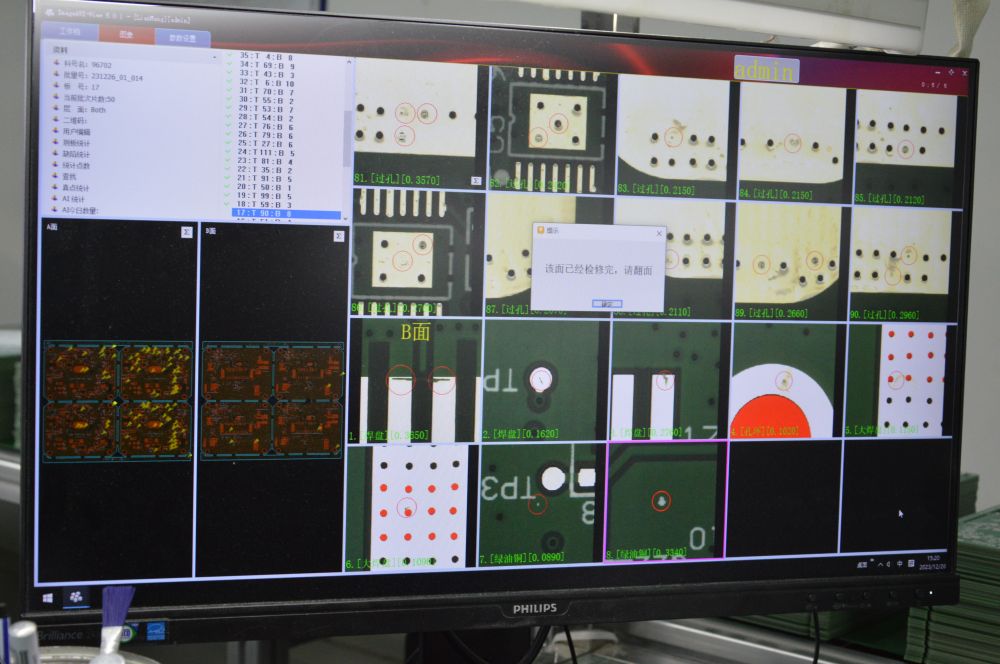

17. Igwe nleba anya nke PCB bụ ngwaọrụ e mere iji nyochaa ọdịdị anya nke mbadamba sekit ma chọpụta mmejọ mmepụta. Igwe a nwere igwefoto nwere mkpebi dị elu na isi ọkụ iji duzie nyocha nke ọma nke elu PCB, na-achọpụta ntụpọ dị iche iche dị ka ncha, corrosion, mmetọ, na okwu ịgbado ọkụ. Na-emekarị, ọ na-agụnye usoro inye nri na nbudata ngwa ngwa maka ijikwa nnukwu batches PCB na ikewapụ bọọdụ ndị akwadoro na ndị jụrụ ajụ. Site n'iji algọridim nhazi ihe onyonyo n'ọrụ, a na-ahazi ntụpọ ndị achọpụtara na akara, na-eme ka nrụzi ma ọ bụ mkpochapụ dị mfe yana karịa. Ekele maka akpaaka na ikike nhazi onyonyo dị elu, igwe ndị a na-eme nyocha ngwa ngwa, na-akwalite nrụpụta yana ọnụ ahịa mbelata. Ọzọkwa, ha nwere ike ịchekwa nsonaazụ nyocha wee mepụta akụkọ zuru oke maka nleba anya nleba anya na nkwalite usoro, n'ikpeazụ na-ebuli ogo ngwaahịa.

Igwe nyocha ọdịdị ọdịdị 1

Igwe nyocha ọdịdị ọdịdị 2

Akara ntụpọ nleba anya

Ihe nnwale mmetọ PCB

18. The PCB ion contamination tester bụ a pụrụ iche ngwá ọrụ tinye n'ọrụ maka ịchọpụta ion contamination na e biri ebi sekit mbadamba (PCBs). N'oge a na-emepụta ngwá electronic, ọnụnọ nke ion na PCB elu ma ọ bụ n'ime osisi nwere ike imetụta ọrụ sekit na àgwà ngwaahịa. N'ihi ya, ntule ziri ezi nke ọkwa mmetọ ion na PCB dị oke mkpa iji kwe nkwa ịdị mma na ntụkwasị obi nke ngwa elektrọn.

19. A na-eji igwe na-enyocha ihe mkpuchi ọkụ na-arụ ọrụ iji na-eduzi ihe mkpuchi na-eguzogide ule voltaji iji kwado na ihe mkpuchi mkpuchi na nhazi nhazi nke eriri sekit na-agbaso ụkpụrụ ọkọlọtọ. Nke a na-achọpụta na bọọdụ sekit na-anọgide na-ekpuchi ya n'okpuru ọnọdụ arụ ọrụ mgbe niile, na-egbochi ndakpọ mkpuchi nwere ike ibute ihe egwu. Site n'ịtụle nsonaazụ ule ahụ, a ga-achọpụta ihe ọ bụla dị n'okpuru na bọọdụ sekit ozugbo, na-eduzi ndị na-emepụta ihe n'ịkwalite nhazi na nhazi nke ụlọ ahụ iji kwalite ogo na arụmọrụ ya.

Igwe na-enyocha ihe mkpuchi voltaji

UV Spectrophotometer

20. UV spectrophotometer: UV spectrophotometer na-etinye n'ọrụ tụọ ìhè absorption àgwà nke photosensitive ihe etinyere sekit mbadamba. Ihe ndị a, nke a na-ejikarị photoresists na-eji na-emepụta bọọdụ sekit a na-ebipụta, na-ahụ maka ịmepụta usoro na ahịrị na mbadamba.

Ọrụ nke UV spectrophotometer gụnyere:

1) Ntụle nke njirimara absorption nke fotoresist: Site na nyochaa njirimara absorption nke photoresist na ultraviolet spectrum range, a pụrụ ikpebi ogo nke ntanye ọkụ ultraviolet. Ozi a na-enyere aka n'ịgbanwe nhazi na mkpuchi mkpuchi nke fotoresisist iji hụ na arụmọrụ ya na nkwụsi ike n'oge fotolithography.

2) Mkpebi nke parampat ikpughe fotolithography: Site na nyocha nke njirimara absorption nke fotoresist, enwere ike ikpebi oke mkpughe fotolithography kachasị mma, dị ka oge mkpughe na ike ọkụ. Nke a na-eme ka ntugharị ziri ezi nke ụkpụrụ na ahịrị na fotoresis si na bọọdụ sekit.

21. pH mita: Na n'ichepụta usoro nke sekit mbadamba, chemical agwọ ọrịa dị ka pickling na alkali ihicha na-emekarị n'ọrụ. A na-eji mita pH eme ihe iji hụ na uru pH nke ngwọta ọgwụgwọ na-anọgide n'ime oke kwesịrị ekwesị. Nke a na-eme ka ọ dị irè, ịrụ ọrụ, na nkwụsi ike nke ọgwụgwọ kemịkalụ, si otú a na-emeziwanye àgwà ngwaahịa na ntụkwasị obi mgbe ị na-ahụ na gburugburu mmepụta ihe dị mma.