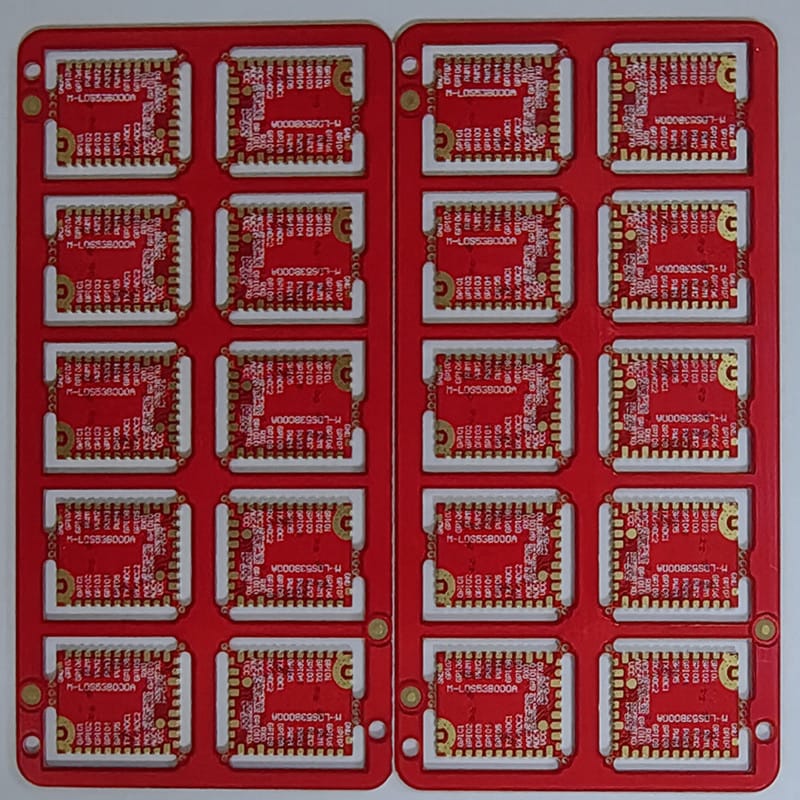

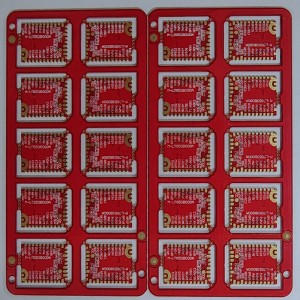

Prototype e biri ebi sekit mbadamba RED solder nkpuchi castellated oghere

Nkọwapụta ngwaahịa:

| Ihe ndabere: | FR4 TG140 |

| Ọkpụrụkpụ PCB: | 1.0+/-10% mm |

| Ọnụọgụ oyi akwa: | 4L |

| Ọkpụrụkpụ ọla kọpa: | 1/1/1/1 oz |

| Ọgwụgwọ elu: | ENIG 2U" |

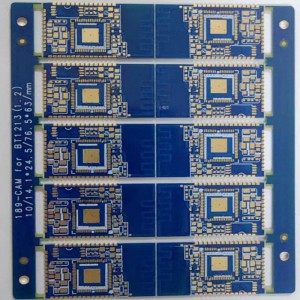

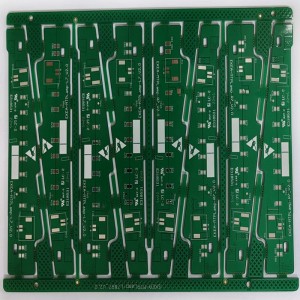

| Ihe mkpuchi ihe na-ere ahịa: | Uhie na-egbuke egbuke |

| Ihuenyo silk: | Ọcha |

| Usoro pụrụ iche: | Pth ọkara oghere na nsọtụ |

Ngwa

Usoro nke plated ọkara oghere bụ:

1. Hazie oghere nke ọkara nke nwere ihe eji egbutu ụdị V abụọ.

2. Mgbochi nke abụọ na-agbakwụnye oghere nduzi n'akụkụ oghere ahụ, na-ewepụ akpụkpọ ahụ ọla kọpa tupu oge eruo, na-ebelata burrs, ma na-eji ndị na-egbu ihe na-eme ka ọ bụrụ ihe na-eme ka ọ dị elu na-agba ọsọ ọsọ.

3. Na-emikpu ọla kọpa ka ọ bụrụ electroplate nke mkpụrụ, nke mere na a na-etinye akwa ọla kọpa na mgbidi oghere nke oghere gburugburu na nsọtụ osisi ahụ.

4. Mmepụta nke mpụta oyi akwa circuit mgbe lamination, ikpughe, na mmepe nke mkpụrụ n'usoro, na mkpụrụ a na-edo onwe ya n'okpuru nke abụọ ọla kọpa plating na tin plating, nke mere na ọla kọpa oyi akwa na oghere mgbidi nke gburugburu oghere na nsọtụ nke osisi na-ejupụta na ọla kọpa oyi akwa kpuchie na kpuchie a tin oyi akwa maka corrosion iguzogide;

5. Ọkara oghere na-akpụ egbutu oghere gburugburu na nsọtụ osisi ahụ na ọkara iji mepụta ọkara oghere;

6. Na nzọụkwụ nke iwepụ ihe nkiri ahụ, a na-ewepụ ihe nkiri mgbochi electrolating nke a na-agbanye n'oge usoro ntinye ihe nkiri;

7. Etching nke mkpụrụ osisi na-etched, na ọla kọpa ekpughere na mpụta oyi akwa na-ewepụ site etching;

8. A na-ewepụ tin tin na-apụ apụ na tin, nke mere na tin dị na mgbidi ọkara oghere nwere ike wepụ ya, akwa ọla kọpa na mgbidi ọkara oghere na-apụta.

9. Mgbe emechara, jiri teepu na-acha uhie uhie na-ejikọta mbadamba unit ahụ, ma wepụ burrs site na eriri alkaline etching.

10. Mgbe nke abụọ ọla kọpa plating na tin plating na mkpụrụ, gburugburu oghere na nsọtụ nke osisi na-egbutu na ọkara na-etolite a ọkara oghere, n'ihi na ọla kọpa oyi akwa nke oghere mgbidi kpuchie na a tin oyi akwa, na ọla kọpa oyi akwa nke oghere mgbidi bụ kpamkpam emebibeghị na ọla kọpa oyi akwa nke mpụta oyi akwa nke substrate Connection, gụnyere ike bonding ike, nwere ike na-arụ ọrụ nke ọma egbochi mgbidi ọla kọpa oyi akwa mgbe ọ na-adọpụpụ mgbidi oyi akwa si ọla kọpa oyi akwa na-mgbochi.

11. Mgbe ọkara oghere akpụ na dechara, fim na-ewepụ na mgbe ahụ etched, nke mere na ọla kọpa elu agaghị oxidized, n'ụzọ dị irè na-ezere omume nke fọdụrụnụ ọla kọpa ma ọ bụ ọbụna obere sekit, na-eme ka mkpụrụ ọnụego nke metallized ọkara oghere PCB circuit osisi.

Ajụjụ

Ọkara oghere ma ọ bụ oghere nke castellated, bụ ọnụ nke nwere stampụ site na igbubi ọkara n'ime ndepụta ahụ. Oghere ọkara nke etinyere bụ ọkwa dị elu nke akụkụ dị elu maka bọọdụ sekit a na-ebipụta, nke a na-ejikarị eme ihe maka njikọ osisi-na-board.

A na-eji Via dị ka njikọ dị n'etiti akwa ọla kọpa na PCB ebe PTH na-emekarị ka ọ buru ibu karịa vias ma jiri ya mee ihe dị ka oghere plated maka ịnakwere ihe ndị na-eduga - dị ka ndị na-abụghị SMT resistors, capacitors, na DIP ngwugwu IC. PTH nwekwara ike iji dị ka oghere maka n'ibu njikọ mgbe vias nwere ike ghara.

Ihe a na-etinye na oghere ndị ahụ bụ ọla kọpa, onye na-eduzi, n'ihi ya, ọ na-enye ohere ka ọkụ eletrik na-agafe na osisi. Ndị na-abụghị plated site na oghere enweghị conductivity, ya mere, ọ bụrụ na ị na-eji ha, ị nwere ike na-enwe bara uru ọla kọpa tracks n'otu akụkụ nke osisi.

Enwere ụdị oghere 3 na PCB, Plated through Hole (PTH), Non-Plated through Hole (NPTH) na Via Holes, ndị a ekwesịghị inwe mgbagwoju anya na oghere ma ọ bụ Cut-outs.

Site na ọkọlọtọ IPC, ọ bụ +/- 0.08mm maka pth, yana +/- 0.05mm maka npth.