Ụkpụrụ nduzi anyị bụ ịkwanyere ụkpụrụ mbụ nke onye ahịa anya ka anyị na-eji ike mmepụta anyị mepụta PCB nke na-emezu nkọwa ndị ahịa. Mgbanwe ọ bụla na nhazi mbụ chọrọ nkwenye ederede n'aka onye ahịa. Mgbe ha nwetara ọrụ mmepụta, ndị injinia MI na-enyocha nke ọma akwụkwọ na ozi niile nke onye ahịa nyere. Ha na-achọpụtakwa ọdịiche ọ bụla n'etiti data ndị ahịa na ike mmepụta anyị. Ọ dị mkpa ịghọta n'ụzọ zuru ezu ebumnobi imewe nke onye ahịa na mmepụta ihe chọrọ, na-ahụ na akọwapụtara ihe niile achọrọ n'ụzọ doro anya ma rụọ ọrụ.

Ịkwalite nhazi nke onye ahịa gụnyere usoro dị iche iche dị ka ịmepụta nchịkọta, ịhazigharị nha ụda, ịgbasa ahịrị ọla kọpa, ịgbasa windo nkpuchi solder, gbanwee ihe odide dị na windo, na ime nhazi nhazi. Emere mgbanwe ndị a ka ọ kwekọọ na mkpa mmepụta yana data nhazi nke onye ahịa.

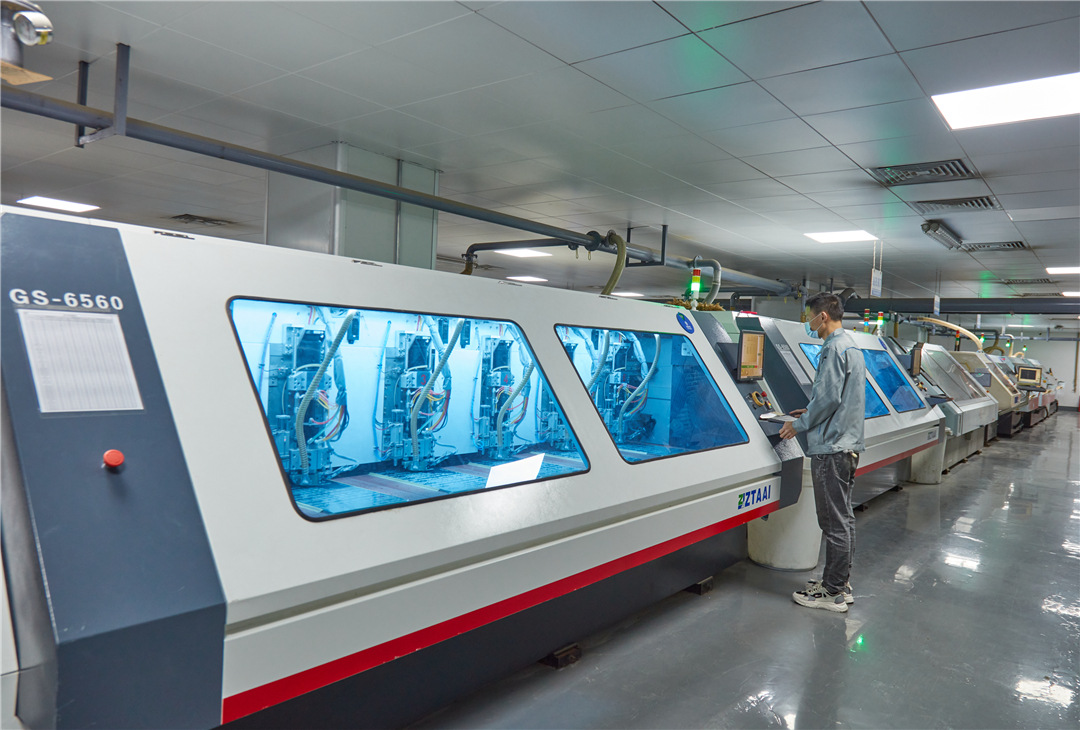

Usoro nke ịmepụta PCB (Boọdụ Circuit Ebipụtara) nwere ike gbarie n'ọtụtụ usoro, nke ọ bụla gụnyere usoro nrụpụta dị iche iche. Ọ dị mkpa ịmara na usoro a dịgasị iche dabere na nhazi nke osisi ahụ. Usoro ndị a na-akọwapụta usoro izugbe maka PCB multi-layer:

1. Ịcha: Nke a na-agụnye trimming na Ibé akwụkwọ ka jirichaa tinye n'ọrụ.

2. Ime Layer Production: Nke a nzọụkwụ bụ isi n'ihi na-eke esịtidem sekit nke PCB.

- Tupu ọgwụgwọ: Nke a gụnyere ihicha PCB mkpụrụ n'elu na iwepu ihe ọ bụla n'elu mmetọ.

- Lamination: Ebe a, a akọrọ ihe nkiri na-arapara n'ahụ PCB mkpụrụ n'elu, na-akwadebe ya maka ụdi image nyefe.

- Ngosipụta: A na-ekpughere ihe mkpuchi mkpuchi na ọkụ ultraviolet site na iji akụrụngwa pụrụ iche, nke na-ebufe ihe oyiyi mkpụrụ osisi na fim akọrọ.

- A na-emepụta ihe ndị ahụ ekpughere, a na-emepụta ihe, na-ewepụ ihe nkiri ahụ, na-emecha mmepụta nke osisi oyi akwa dị n'ime.

3. Nyocha nke ime: Nzọụkwụ a bụ isi maka ịnwale na ịrụzi sekit osisi.

- AOI optical scanning na-eji tụnyere PCB oyiyi osisi na data nke ezigbo mma osisi iji chọpụta ntụpọ dị ka oghere na dents na osisi oyiyi. - Mmebi ọ bụla nke AOI chọtara na-arụzi ya site n'aka ndị ọrụ dị mkpa.

4. Lamination: Usoro nke ijikọ ọtụtụ n'ime oyi akwa n'ime otu osisi.

- Browning: Nzọụkwụ a na-eme ka njikọ dị n'etiti bọọdụ na resin dịkwuo mma ma mee ka mmiri dị n'elu ọla kọpa dịkwuo mma.

- Riveting: Nke a gụnyere ịkpụ PP ka ọ bụrụ nha kwesịrị ekwesị iji jikọta bọọdụ oyi akwa dị n'ime ya na PP kwekọrọ.

- Igwe ọkụ na-ekpo ọkụ: A na-agbanye n'ígwé ahụ ọkụ ma sie ike n'ime otu nkeji.

5. Ịkwọ ụgbọ mmiri: A na-eji igwe na-egwupụta ihe na-emepụta oghere nke dị iche iche dayameta na nha na osisi dị ka nkọwa ndị ahịa si dị. Oghere ndị a na-akwado nhazi ngwa mgbakwunye na-esote ma nyere aka na ikpochapụ okpomọkụ site na osisi.

6. Ihe mkpuchi ọla kọpa nke mbụ: Oghere ndị a kụpụrụ n'elu osisi bụ ọla kọpa iji hụ na arụmọrụ gafere n'ígwé osisi niile.

- Deburring: Nzọụkwụ a na-agụnye iwepụ burrs na nsọtụ nke oghere osisi iji gbochie ịkwanye ọla kọpa na-adịghị mma.

- Mwepụ gluu: a na-ewepụ ihe ọ bụla gluu n'ime oghere ahụ iji kwalite nrapado n'oge micro-etching.

- Oghere ọla kọpa: Nzọụkwụ a na-eme ka a mata conductivity gafee niile osisi n'ígwé na-abawanye n'elu ọla kọpa ọkpụrụkpụ.

7. Nhazi Layer Outer: Usoro a yiri usoro oyi akwa dị n'ime na nzọụkwụ mbụ na e mere iji kwado ihe okike sekit na-esote.

- Tupu ọgwụgwọ: A na-ehicha elu osisi ahụ site na pickling, egweri, na ihicha iji welie ihe nkiri akọrọ.

- Lamination: A akọrọ film na-arapara n'ahụ PCB mkpụrụ n'elu na nkwadebe maka ụdi image nyefe.

- Ngosipụta: mkpughe ọkụ UV na-eme ka ihe nkiri akọrọ na osisi banye na steeti polymerized na enweghị polymerized.

- Mmepe: A na-agbaze ihe nkiri akọrọ na-enweghị polymerized, na-ahapụ oghere.

8. Nke abụọ ọla kọpa plating, Etching, AOI

- Ọla kọpa nke abụọ: A na-eme usoro electroplating na ngwa ọla kọpa kemịkalụ na mpaghara oghere ndị ihe nkiri kpọrọ nkụ anaghị ekpuchi. Nke a na nzọụkwụ na-agụnye n'ihu ịkwalite conductivity na ọkpụrụkpụ ọla kọpa, sochie tin plating iji chebe iguzosi ike n'ezi nke ahịrị na oghere n'oge etching.

- Etching: A na-ewepụ ọla kọpa isi n'ime ihe nkiri akọrọ nke dị n'èzí (ihe nkiri mmiri) site na ntinye ihe nkiri, etching na tin tin usoro, na-emecha sekit dị n'èzí.

- AOI oyi akwa: Dị ka oyi akwa dị n'ime AOI, a na-eji nyocha anya AOI chọpụta ebe ndị nwere ntụpọ, nke ndị ọrụ dị mkpa na-arụzi ya.

9. Ngwa mkpuchi solder: Nke a na-agụnye itinye ihe mkpuchi mkpuchi iji chebe osisi ma gbochie oxidation na nsogbu ndị ọzọ.

- Pretreatment: The osisi na-enweta pickling na ultrasonic ịsacha iji wepụ oxides na dịkwuo ọla kọpa elu roughness.

- Mbipụta: A na-eji ink na-eguzogide solder kpuchie ebe PCB nke na-achọghị ire ere, na-enye nchebe na mkpuchi.

- Tupu ịsa achịcha: Ihe mgbaze dị na ink nkpuchi solder akpọnwụwo, na ink na-esi ike na nkwadebe maka ikpughe.

- Ngosipụta: A na-eji ọkụ UV na-agwọ ink mkpuchi ihe na-ere ihe, na-ebute nguzobe nke polymer dị elu site na polymerization photosensitive.

- Mmepe: A na-ewepụ ihe ngwọta sodium carbonate na ink na-enweghị polymerized.

- Mgbe emechara achịcha: Ink na-agbasi ike nke ọma.

10. Text Printing: Nke a nzọụkwụ gụnyere ibipụta ederede na PCB osisi maka mfe ntụaka n'oge ụdi soldering usoro.

- Pickling: A na-ehicha elu osisi ahụ iji wepụ oxidation ma welie adhesion nke ink obibi akwụkwọ.

- Ederede Ederede: A na-ebipụta ederede achọrọ iji kwado usoro ịgbado ọkụ na-esote.

11.Surface Ọgwụgwọ: The iferi ọla kọpa efere na-enweta ọgwụgwọ elu dabere na ndị ahịa chọrọ (dị ka ENIG, HASL, Silver, Tin, Plating gold, OSP) iji gbochie nchara na oxidation.

12.Board Profaịlụ: A na-emepụta osisi ahụ dị ka ihe ndị ahịa chọrọ, na-eme ka SMT patching na mgbakọ dị mfe.